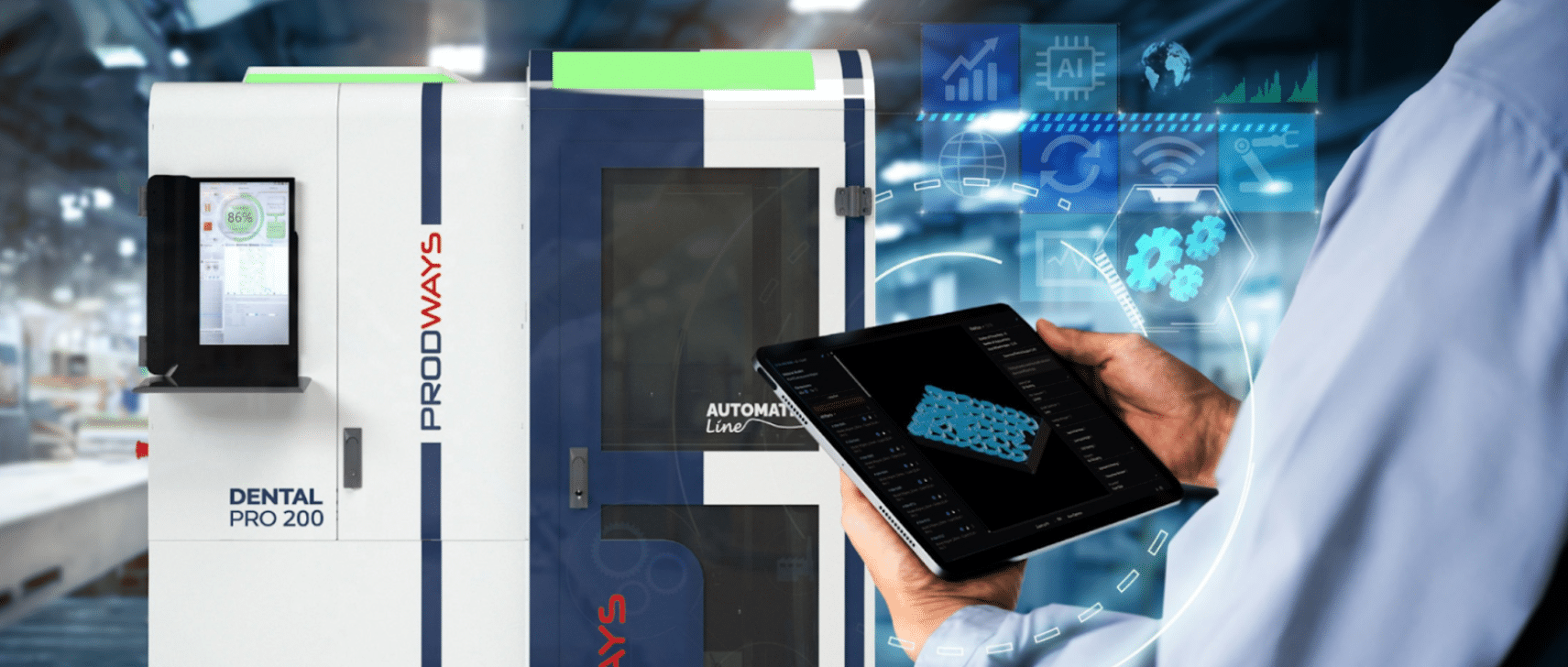

The dental industry is undergoing a major transformation.

With the growing demand for custom-made devices — resin removable prosthetics, aligners, surgical guides, night guards — dental labs have no choice but to modernize.

The key to this evolution? The automation of dental 3D printing, a topic we explore in detail in our latest e-book.

Are you a dental technician, lab manager, or simply curious about new 3D printing production technologies?

This guide is for you.

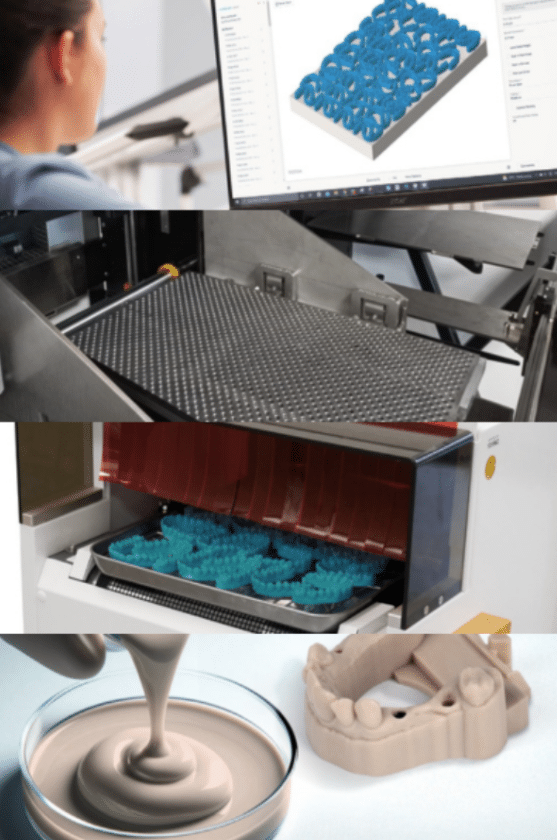

By downloading our e-book, you’ll learn how to turn your lab into a true digital factory, capable of meeting today’s requirements:

speed, quality, volume, and traceability.

Why is Automation Now Essential for Dental 3D Printing?

Beyond modernization, automation optimizes every stage of the dental workflow.