3D printing has transformed the dental sector, enabling the rapid and precise production of models for aligners, dentures, crowns & bridges, custom trays, orthodontics, and implantology. This technology offers a level of customization and quality previously unattainable with traditional methods. However, not all printing technologies are equal: depending on your priorities—precision, volume, cost, or durability—the choice of technology will directly impact results. A thoughtful strategy, from technology selection to workflow organization, is therefore essential to maximize clinical and industrial success.

What Are the Main Dental 3D Printing Technologies?

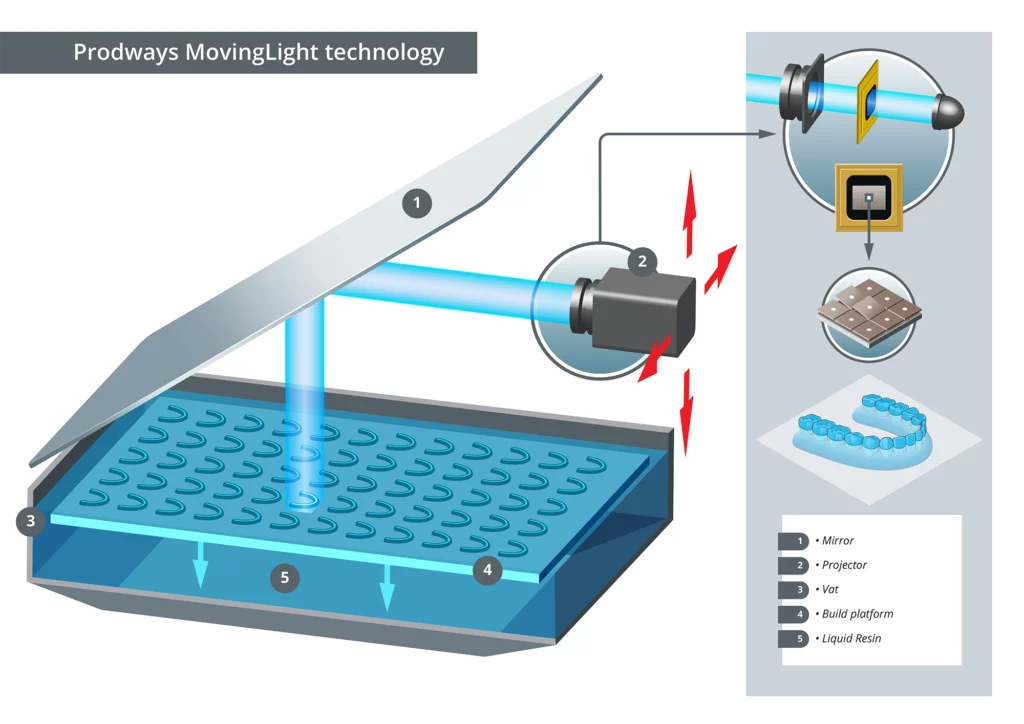

Two technologies dominate the dental market: Digital Light Processing (DLP), and Liquid Crystal Display (LCD). All rely on photopolymerization, but differ in their light source and projection method, which influences precision, speed, and part durability.