Specific applications of 3D printing in design, prototyping, and production for aerospace.

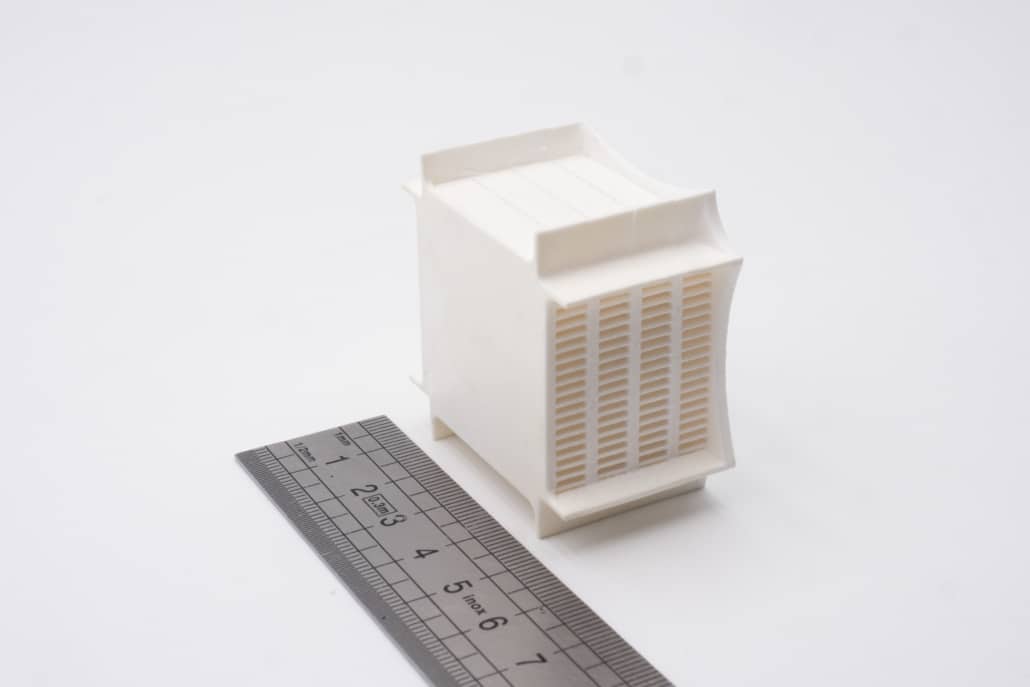

Prodways’ CERAM PRO series enables both small-batch production and scalable industrial manufacturing of ceramic parts, allowing the creation of intricate, lightweight designs for aerospace. 3D printing makes it possible to produce high-performance turbine cores, optical instruments, and other complex components that traditional methods cannot achieve.

By leveraging digital warehousing, manufacturers can print parts on demand, reducing inventory requirements and ensuring timely delivery of the right components. This capability supports flexible production at any scale, from prototypes and limited runs to full-scale industrial series, providing significant cost savings and operational efficiency in fast-paced industries where performance is critical.