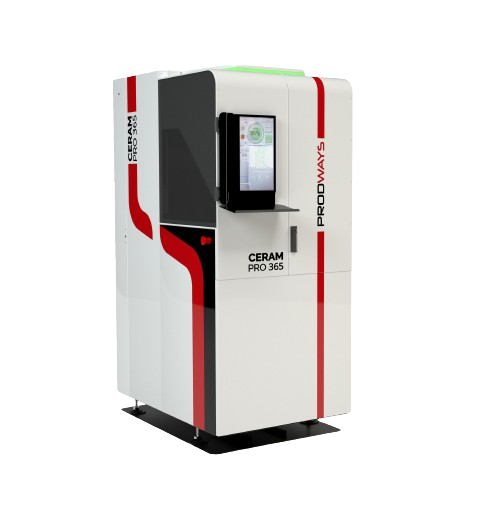

From April 14 to 17, 2026, Prodways Printers and its partner Tethon3D will be coexhibiting at ceramitec 2026 in Munich, a key international event for the ceramics industry. At booth A6.232, we will present ceramic parts produced with our CERAM PRO 365 system, alongside technical slurries developed by Tethon 3D. The focus: real-world applications in aerospace casting, semiconductors and an array of other demanding technical applications.

On site, Vincent Icart (Deputy Managing Director) and our Sales team will be available to discuss projects and answer technical questions in collaboration with our Tethon partners