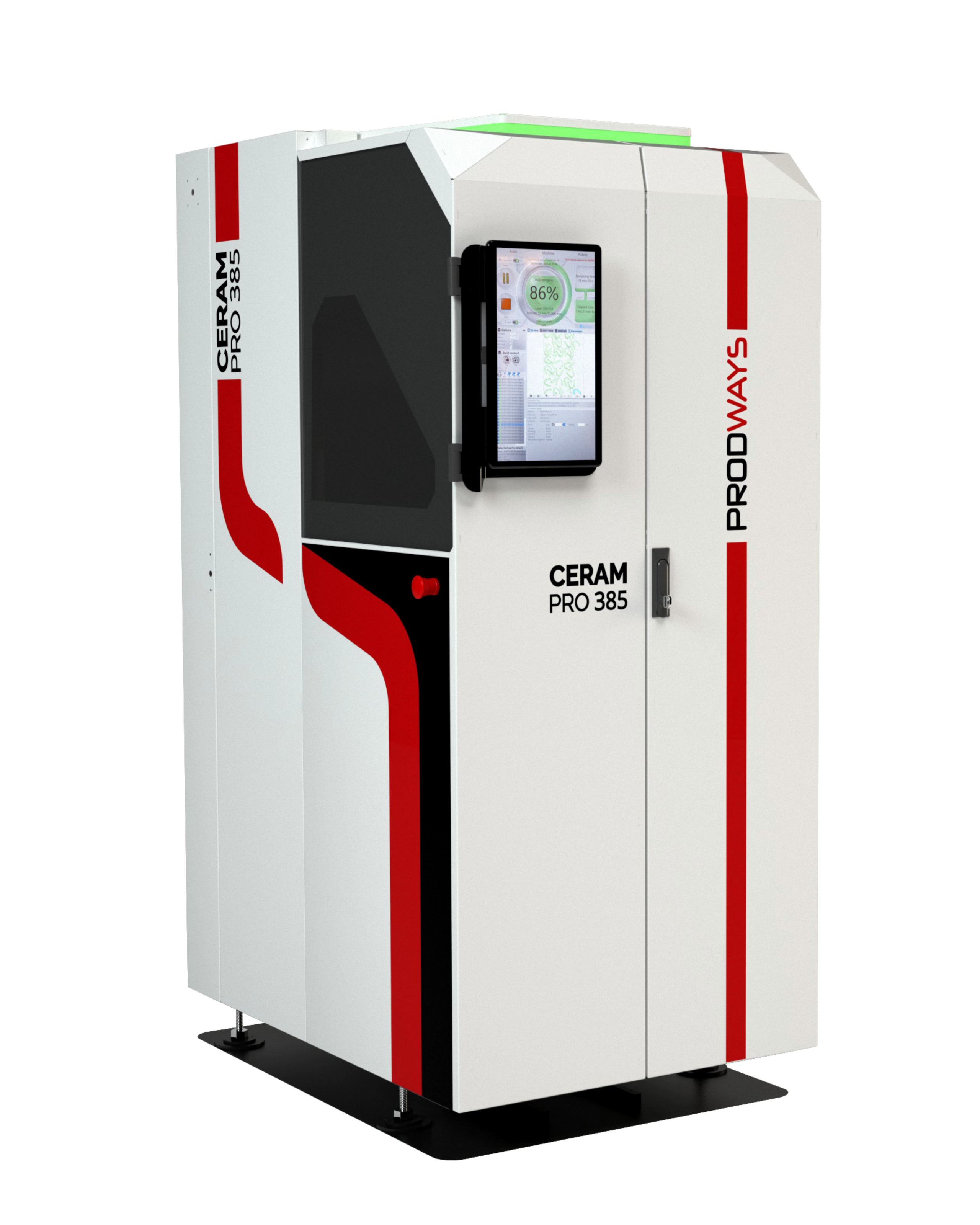

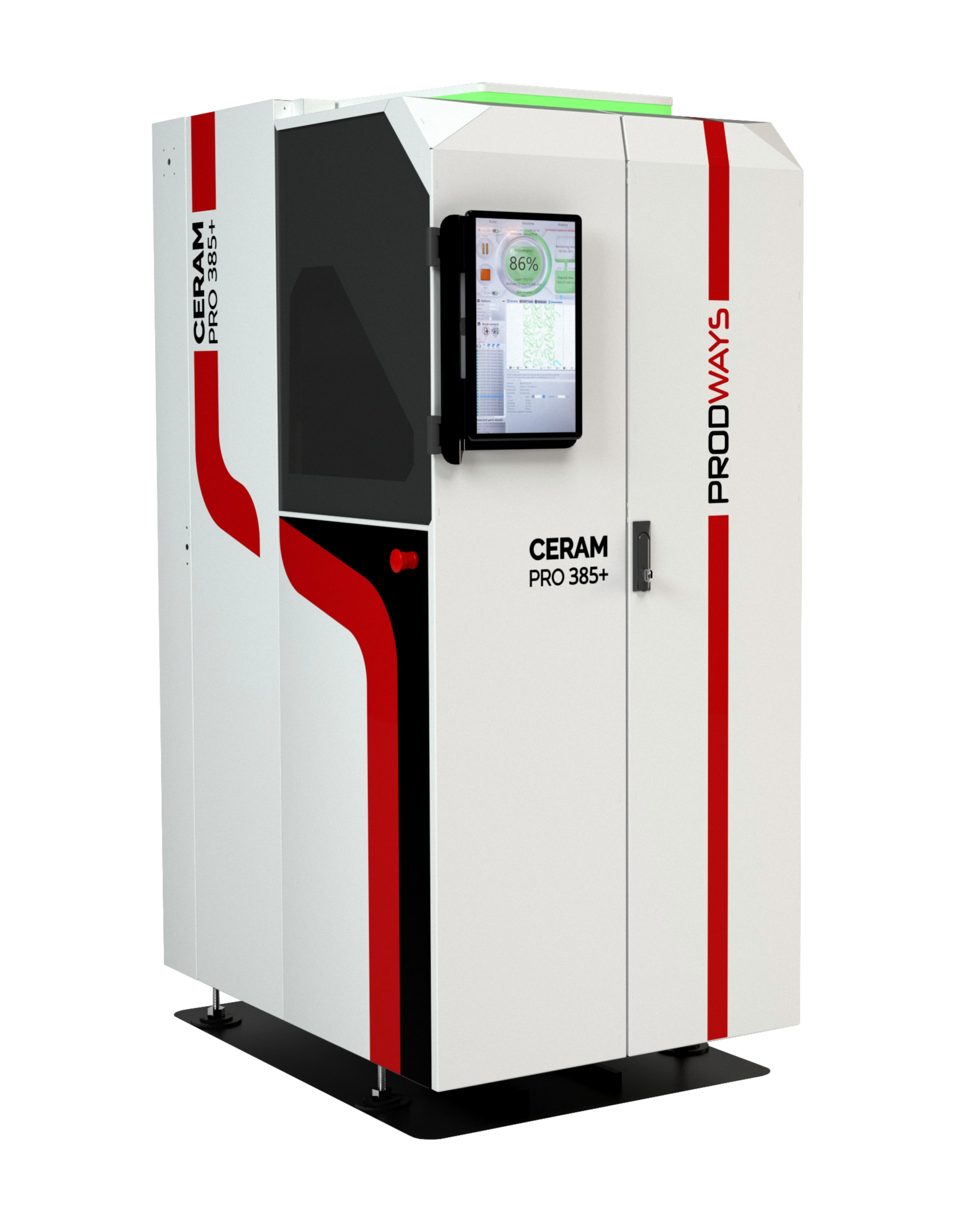

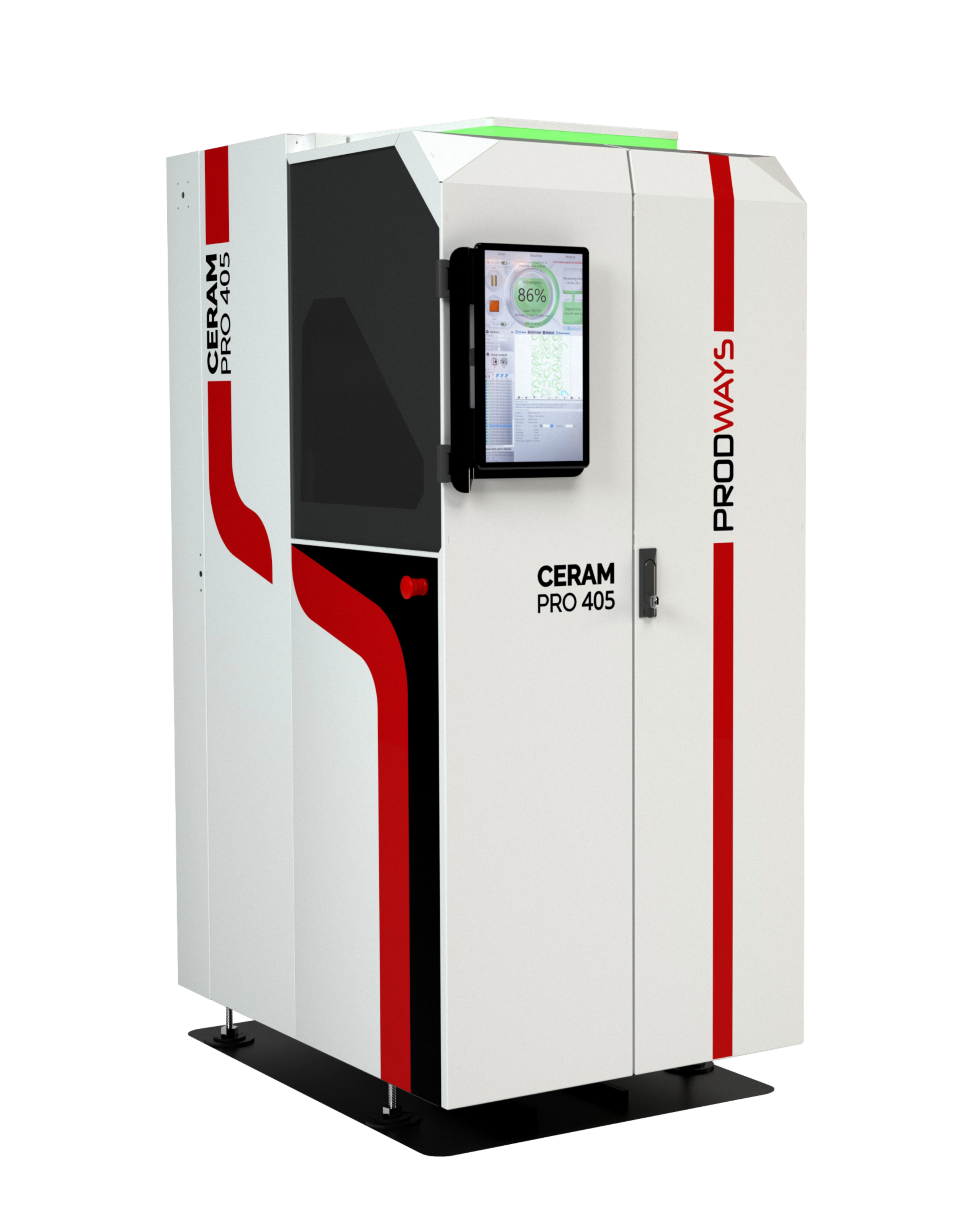

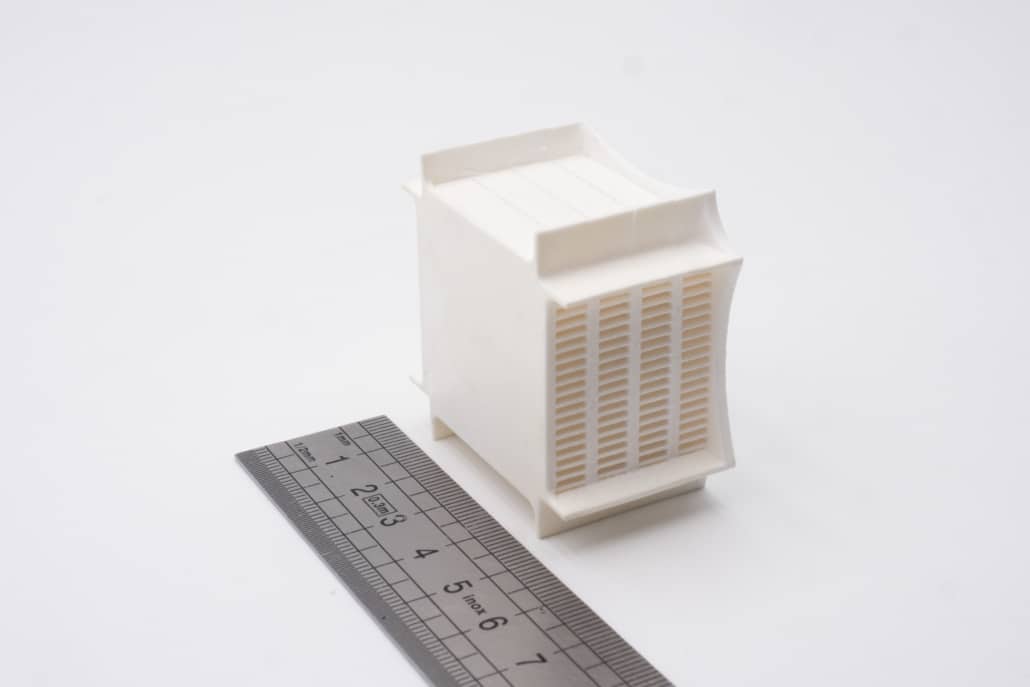

The CERAM PRO series from Prodways supports advanced additive manufacturing services for ceramics, featuring a fully integrated technical system designed to streamline both production and prototyping processes. This versatile material and print platform enables high-precision 3D printing of ceramic parts, from simple prototypes to complex industrial components, with consistent accuracy and excellent surface quality.

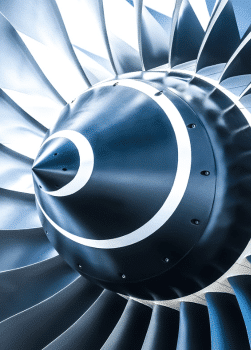

By delivering repeatable, reliable results, the system allows manufacturers to upgrade production workflows, optimize efficiency, and maintain exceptional product quality. With its flexible series of printers, CERAM PRO supports a variety of additive manufacturing processes and ceramic materials, including 3D printed ceramics for aerospace, automotive, investment casting, and industrial R&D applications.

Whether for high-volume production or specialized prototyping, this additive manufacturing solution ensures precise material handling, uniform surface finish, and dependable performance. From the latest 3D ceramic printer technologies to scalable production setups, CERAM PRO empowers businesses to innovate and achieve outstanding results in ceramic additive manufacturing.

FAQ