HRL Laboratories is a world-renowned research center based in Malibu, California. Now jointly owned by General Motors and Boeing, HRL has a long history of breakthrough innovations in materials science, electronics, and aerospace technologies. Their expertise in ceramics and composites makes them a strategic partner for pushing the boundaries of additive manufacturing.

Polymer-derived ceramics (PDCs) : A Materials Revolution

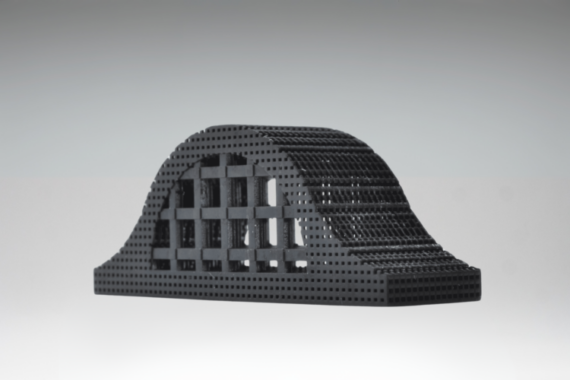

Polymer-derived ceramics (PDCs) are an exciting class of materials that begin as liquid polymers and, through high-temperature pyrolysis, are transformed into advanced ceramics. This unique route allows engineers to shape complex components using 3D printing before converting them into lightweight, heat-resistant, and durable ceramics. PDCs are increasingly important for aerospace, energy, and defense applications where extreme environments demand materials that combine design flexibility with outstanding performance. This unique shaping method allows to alleviate many limitations from conventional AM shaping methods, in particular the binder burn-out and sintering associated engineering challenges.