Building a Complete Ecosystem: How Prodways, Tethon 3D and LBBC Are Enhancing the Investment Casting Workflow

Investment casting is evolving. Foundries are moving away from traditional methods and embracing digital workflows that enable higher precision, repeatability, and process efficiency. From the design of intricate parts to their final casting, every step must align perfectly to meet today’s demanding quality standards.

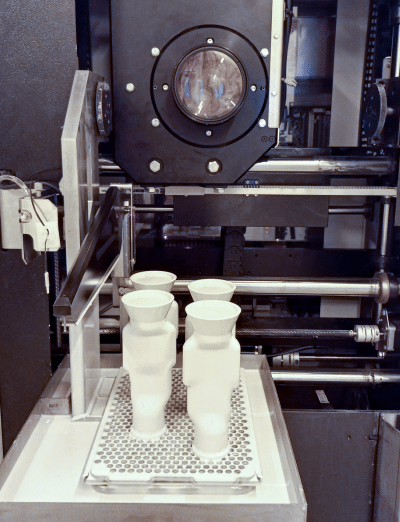

To support this shift from traditional casting to digital workflows, Prodways, Tethon 3D, and LBBC Technologies offer a complete, integrated ecosystem — combining software, industrial 3D printing, advanced materials, and post-processing solutions into a seamless, end-to-end workflow.