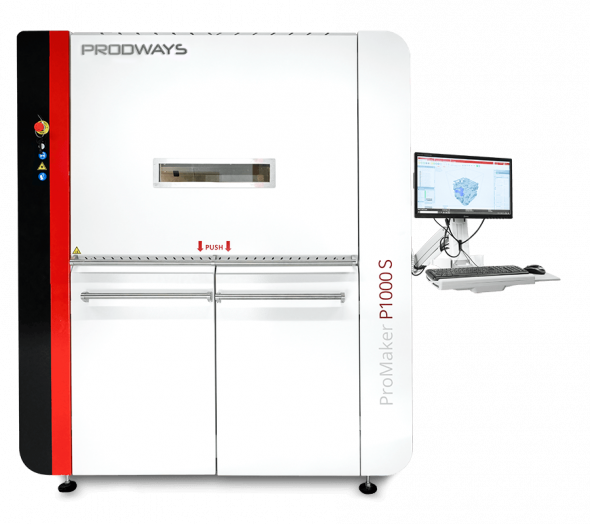

3D Printers » Selective Laser Sintering (SLS) » ProMaker P1000 S

ProMaker P1000 S

Affordable and flexible.

The ProMaker P1000 S is an SLS industrial printer. Based on Selective Laser Sintering technology, it enables series production at an affordable cost while meeting the constraints of industrial production.