The Global Clear Aligner Market

It’s no secret that the global clear aligner market is exploding. Align Technology, creators of Invisalign, report that over 10 million people have used their product to date to straighten their smiles. The global clear aligner market was valued at $2.4 billion in 2020 and is expected to grow to $15.9 billion by 2028.

What’s driving this growth? One of the main reasons is that clear aligners are less invasive method to straightening teeth versus traditional braces.

Another reason is the ‘The Zoom Effect’. Many people have been looking at their unedited image, sometimes on a daily basis, and not liking their smile. Enter a convenient alternative for changing that – the clear aligner.

A Dental Solution That is not Just About Aesthetics

The benefits of straight teeth don’t just start and end with looks. Straight teeth can help reduce your risk of cavities, gum inflammation and disease, and aid in a proper bite. Misaligned teeth can lead to the chipping of teeth from grinding, which can also lead to jaw pain and headaches.

The American Dental Association conducted a poll of its members and found that the global pandemic has led to a 59 percent increase in teeth grinding and clenching. This has resulted in a 53 percent increase in jaw pain, all of which can be brought on by stress.

While one should always get a professional opinion before making any decision to straighten their teeth, clear aligners are an excellent solution for anyone looking to treat mild to moderate misalignment conditions.

Advanced Dental Solutions for Clear Aligner Production

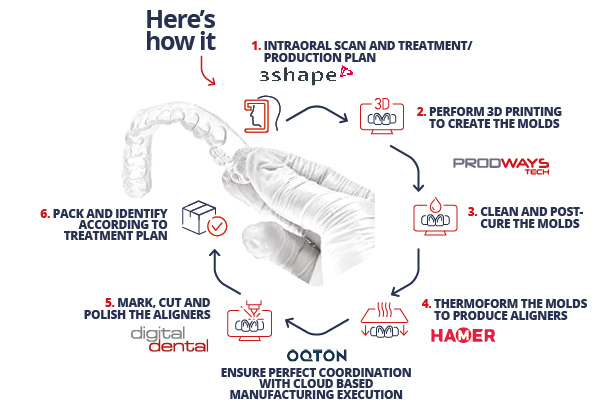

To address the growing need for the reliable, high-throughput manufacturing systems of clear aligners, Prodways Tech has partnered with the leading players in the world of digital dentistry. The result is a fully optimized and validated ecosystem for the industrial production of clear aligners.

The keys to a successful dental workflow are integrated systems and open platforms that allow every piece of a technology to essentially ‘talk’ to each other. It includes not only the hardware elements, such as the intraoral scanner, 3D dental printer and post-processing devices, it also encompasses the software and materials.

Why should you invest in implementing a seamlessly integrated hardware and software ecosystem? Three main reasons:

- It delivers a harmonious experience with precision and quality at each step of the process.

- There is continuous communication between the entire production chain, which reduces human error.

- It can help you take your dental business to the next level with greater efficiency in terms of cost and ROI and delivers a better patient experience.