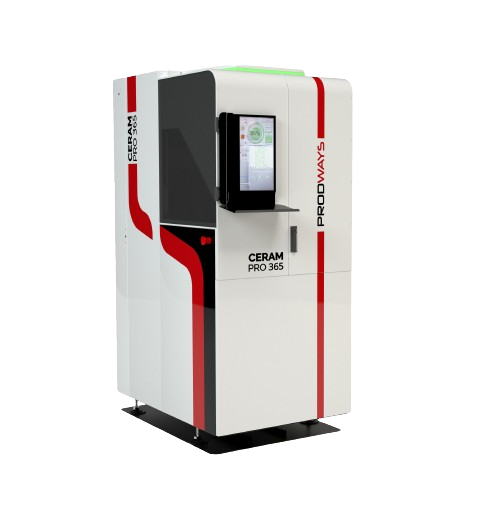

3D Printers » MOVINGLight® DLP Ceramic Resins » CERAM PRO 365

CERAM PRO 365

The CERAM PRO 365 is the complete solution in ceramic 3D printing offered by Prodways Printers. Designed to work seamlessly with SILICA SICAST 1200 and ALUMINA A100 resins from TETHON 3D, a trusted partner in the development of materials and applicative support, this system is based on patented MOVINGLight® top-down technology. Ideal for a wide range of industrial applications, whether for investment casting, technical ceramics, or research and development, the CERAM PRO 365 delivers exceptional flexibility and precision.