To maintain growth and develop business in a rapidly changing industry, a digital workflow is essential for your 3d dental lab. A fully digital workflow allows dental labs to reach production standards that are impossible to reach with traditional work methods.

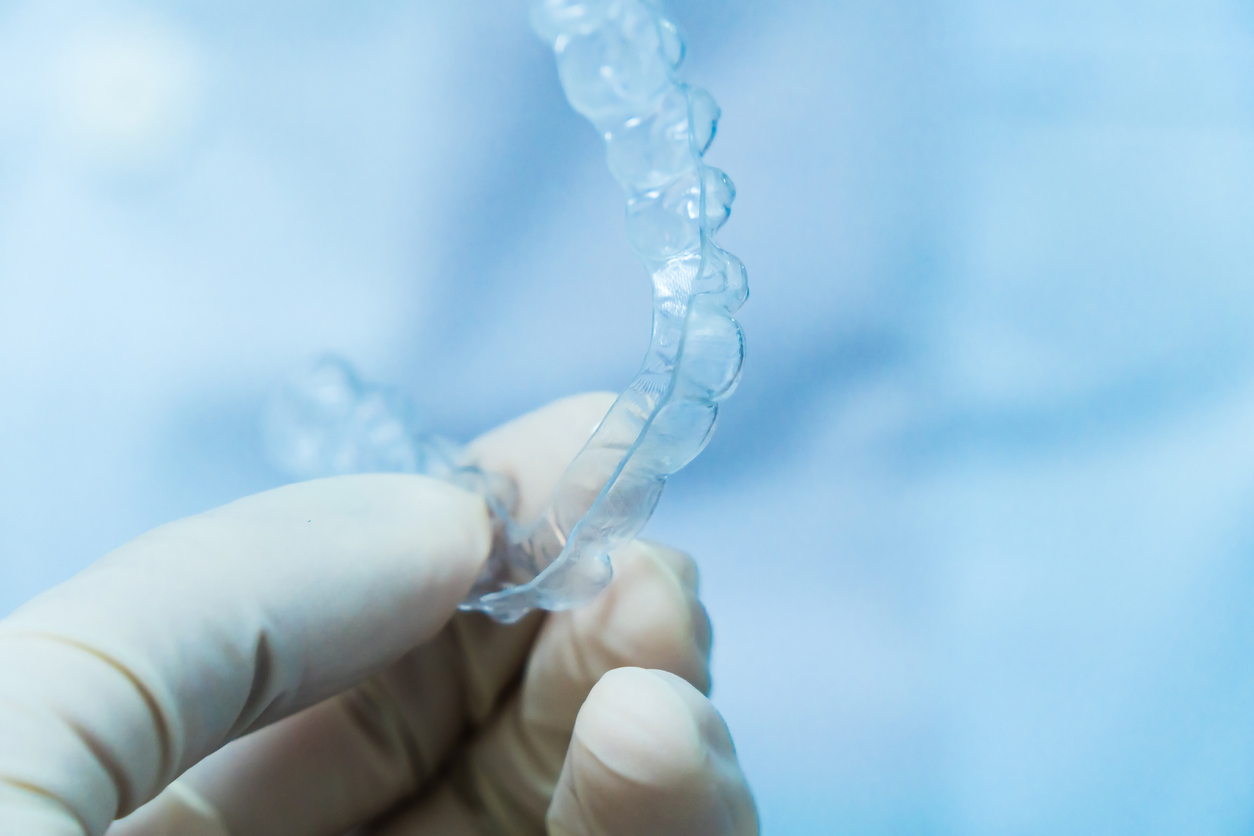

We are talking about the ability to produce thousands of invisible dental aligners per day per day with automated processes and a consistent, validated ecosystem. Regardless of the size of your lab, there are 3D printing solutions for your business with an integrated workflow from start to finish to work more cost-effectively and efficiently while maintaining the highest level of quality.

Digital workflow solutions begin with a complete software!

Behind every 3D model, there is software that can create it and communicate with every touch point at every stage from design to production via an industrial 3D printer. Schematically, the digital workflow software consists of three main steps:

- Scanning: you scan in-house or via intraoral scanners to create the data that is then processed by the software.

- Design: the software allows you to create the STL files that will be used or outsource this work to a specialized design center.

- Manufacturing: you can manufacture your products yourself or use a third-party manufacturer.